Carbon Capture and Storage, known as CCS, is increasingly recognized as a vital strategy in reducing global CO₂ emissions. To meet the targets of the Paris Agreement, the entire CCS value chain must be scaled rapidly. One of the most critical cost bottlenecks in that chain is transportation. Today, both marine and onshore transport of liquefied carbon dioxide represent between 40 and 50 percent of the overall cost of CCS.

The challenge lies in scale. Most current transport solutions use relatively small, inefficient tanks that do not match the growing demand for high volume CO₂ transfer between capture and storage or utilization sites. This is where LPV cargo tank technology makes a dramatic impact by enabling vessels to carry more, cost less, and operate more efficiently.

The Cost of Inefficiency in Traditional Tank Design

Most CO₂ carriers today use cylindrical or bilobe tanks that were never designed for the optimal use of hull space. These traditional shapes limit how much cargo can be stored within the same footprint and often result in longer vessels, more tanks, and higher operational complexity.

This inefficiency drives up both capital expenditure and operating costs. It also creates limits on vessel design flexibility, leaving shipowners with constrained layouts that cannot be scaled without significant cost increases.

As the shipping industry moves toward supporting large scale CCS, the inefficiency of current tank designs becomes a major financial and logistical burden.

How LPV Cargo Tanks Change the Game

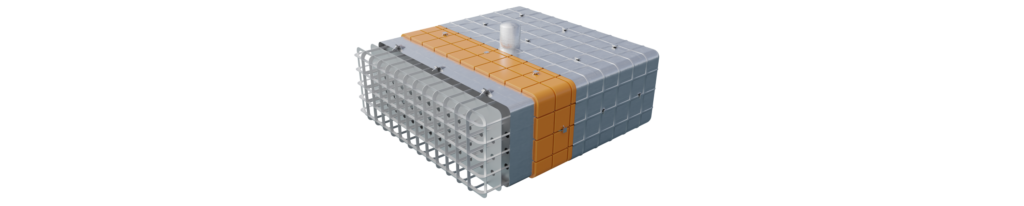

The LPV, or Lattice Pressure Vessel, changes the approach entirely. Unlike cylindrical tanks, LPV tanks are prismatic and fully scalable in both shape and size. This means they can be designed to match the optimal hull geometry rather than forcing the hull to adapt to the tank.

This flexibility allows for more efficient cargo tank placement, reduces vessel length, and lowers the number of tanks required onboard. Because the design is pressure capable up to and beyond 30 barg, LPV tanks are suitable for both low and medium pressure LCO₂ applications. They support long range, large scale transport while optimizing every cubic meter of space available inside the hull.

Case Study: 40000 Cubic Meter LCO₂ Carrier with LPV

A real world case evaluated a 40000 cubic meter LCO₂ carrier with 8 barg pressure specification. Traditional tank design required seven separate tanks and a vessel length well above the efficient range.

By switching to LPV cargo tanks, the number of tanks was reduced from seven to three. The total weight of the containment system remained at 5800 tons, but the vessel length was shortened by 40 meters. These improvements alone generated more than 12 million US dollars in capital expenditure savings.

Additionally, fuel consumption dropped due to the more compact and hydrodynamic hull design, further reducing operating costs and emissions across the vessel’s lifetime. For shipowners and operators, this level of efficiency makes LCO₂ shipping not just feasible, but financially attractive.

Design Flexibility That Matches Your Strategy

LPV tanks can be customized to meet the needs of any LCO₂ transport scenario. Whether you are developing a low pressure carrier, a high pressure shuttle ship, or a modular barge for regional transport, LPV offers the flexibility to meet the project’s exact volume, pressure, and integration requirements.

Tanks can be shaped to fit into existing ship hulls for retrofits or built into optimized newbuild hulls for maximum efficiency. In both cases, the result is increased volume utilization, reduced structural complexity, and a lower cost per cubic meter shipped.

Unlocking the Future of CO₂ Shipping Through Scalability

The key to reducing cost in any logistics chain is scale. LPV technology supports that scale in a way no other tank solution currently can. The free shape and free size design allows operators to reduce the number of tanks, simplify systems, and reduce the number of valves, piping, and instrumentation required. This reduces weight, complexity, and overall cost of ownership.

As global demand for CO₂ transport grows, LPV provides a scalable and future ready platform that adapts to evolving regulatory and operational requirements.

Conclusion: The Strategic Advantage of LPV for LCO₂ Carriers

Shipping is the critical link in a cost effective CCS value chain. Traditional tank designs cannot keep up with the volume, space, and cost efficiency needed to enable large scale deployment. LPV cargo tanks offer a powerful solution that optimizes vessel performance, lowers cost, and increases profitability.

By switching from cylindrical tanks to LPV, owners and designers can unlock higher revenue, reduce emissions, and gain a lasting competitive edge in the emerging LCO₂ market.