Reinventing Energy Transport. Building Smarter Solutions.

Our LATTICE Pressure Vessel (LPV) technology enables safe and efficient storage of all liquefied gases. By optimizing space and reducing costs, we support global industries in achieving reliable energy supply and long-term sustainability.

Pioneering LPV Technology for a Sustainable Future

Discover how our optimized containment solutions transform transform maritime operations, energy infrastructure, and decarbonization — delivering efficiency, safety, and long-term value worldwide.

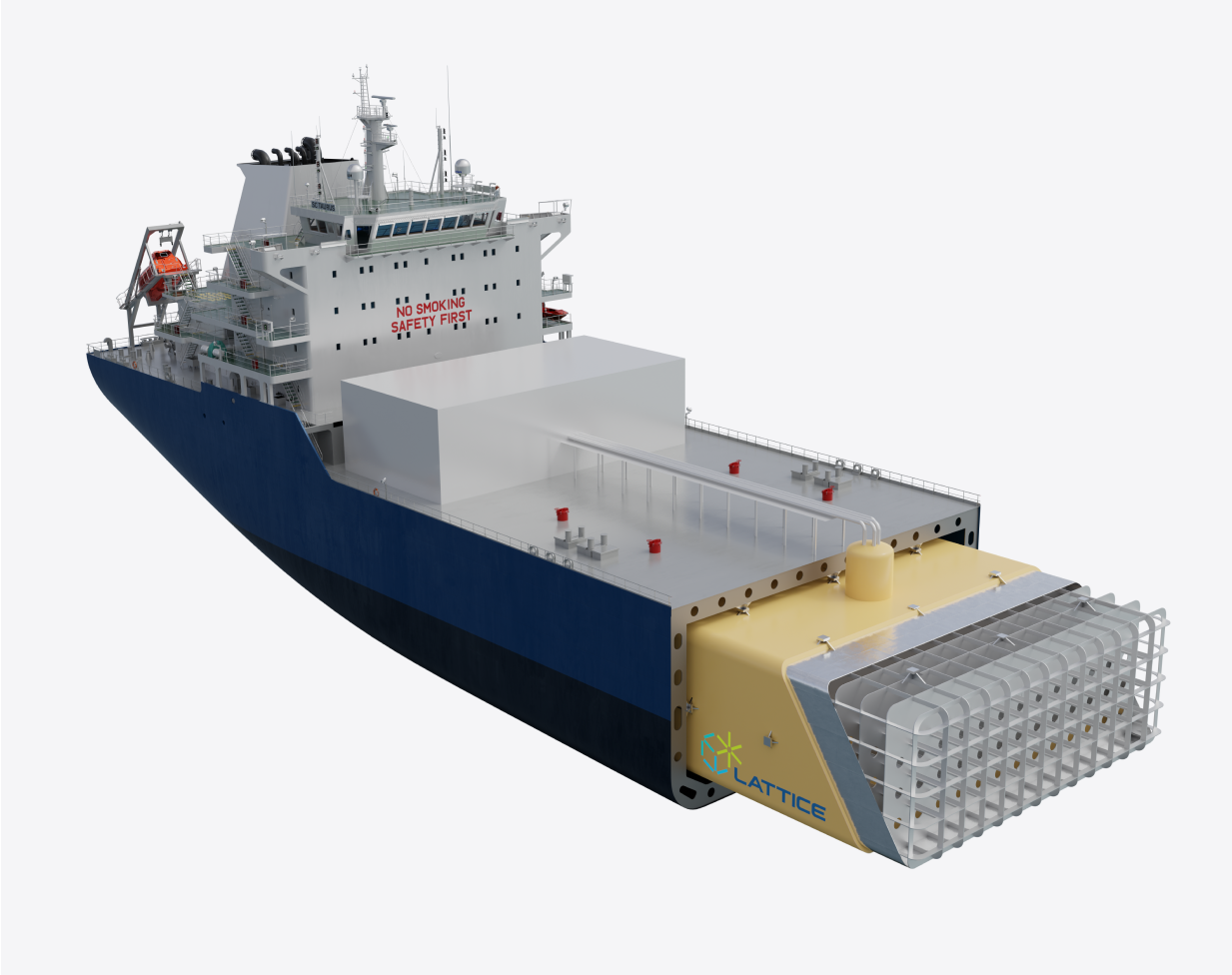

Maritime

Our LPV fuel and cargo solutions maximize storage capacity for LNG, ammonia, CO2, and any other liqufied gas. By enabling cleaner shipping and scalable offshore projects, we help maritime industries transition toward zero-emission operations.

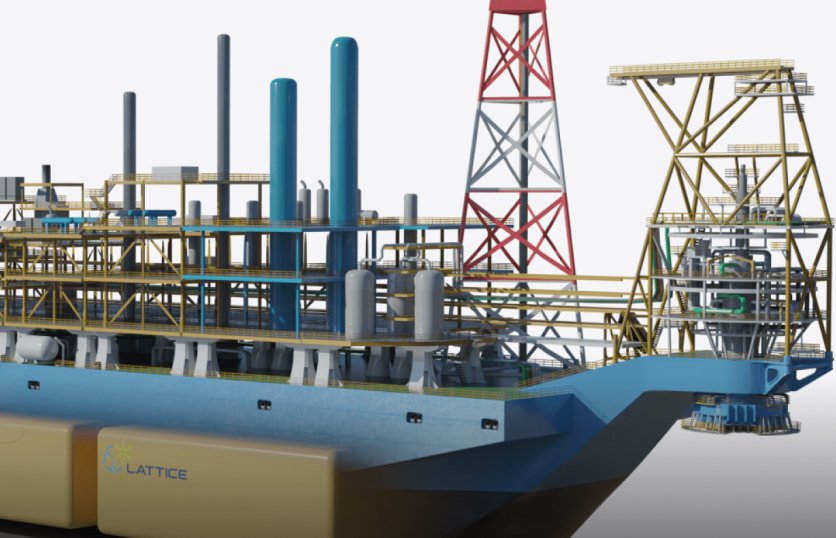

Energy Infrastructure

New Energy & Decarbonization

Benefits of working with Lattice international

LPV Technology Expertise

LPV Technology Expertise

We design advanced containment solutions for liquefied gases, such as LNG, LH₂, LNH₃, and LCO₂, combining flexibility in shape with pressure-loading capability to maximize efficiency and safety in demanding energy applications.

Proven Maritime Solutions

Proven Maritime Solutions

We deliver scalable containment systems tailored to the maritime sector — including fuel and cargo storage for LNG, ammonia, hydrogen, captured CO₂, and more. Our technology is already in use on vessels around the world, helping operators decarbonize while maximizing range, safety, and cargo capacity.

Deep Industry Knowledge

Deep Industry Knowledge

With decades of engineering and operational experience, our team understands the practical challenges of deploying new energy systems. From shipyards and EPCs to industrial sites and infrastructure hubs — we help turn complex requirements into real-world solutions.

Stakeholder-Centered Impact

Stakeholder-Centered Impact

We work closely with clients, regulators, and technology partners to ensure our solutions deliver measurable value — whether it’s lowering emissions, reducing cost per ton of CO₂, or accelerating project timelines. Every engagement is built around long-term, verifiable impact.

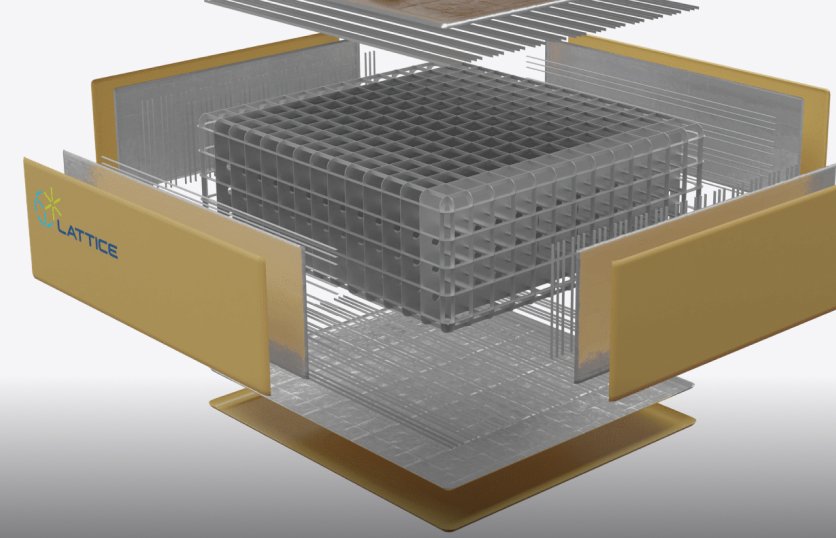

Pressure is no match for the LPV!

Pressure loading

The pressure loading capabilities of the LPV are enabled by the internal lattice structure. Pressure loads are distributed within the grid structure, alleviating stresses on the tank shell.

Up to 50% higher volume utilization with the flexible LPV design

Flexible

The internal lattice structure allows for limitless flexibility of the tank design, enabling a new design approach for ship- and onshore infrastructures.

Enable economies of scale with the LPV!

Scalable

With the internal lattice structure, high shell thickness is no longer an issue, enabling tank scalability to any size and design pressure while keeping the overall plate thicknesses and weight down.

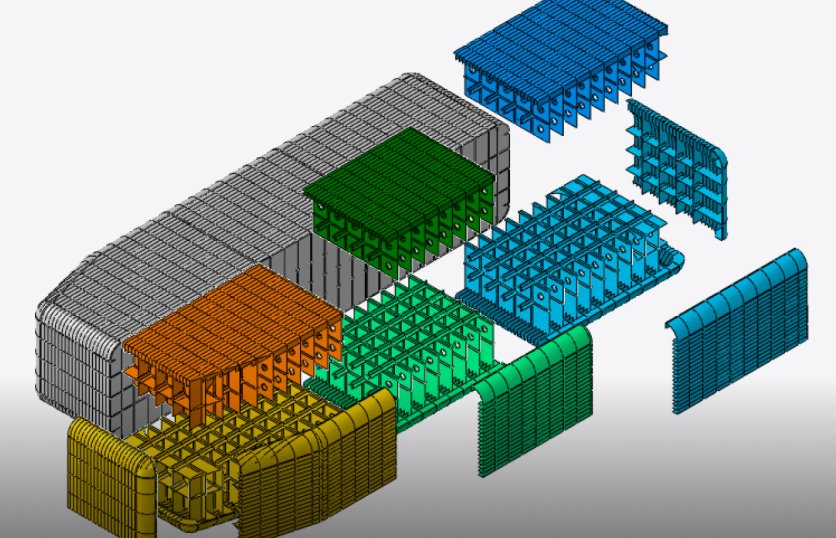

Efficient Fabrication Process

Repetitive structures enable high level of automation and efficiency throughout the fabrication process. All the main parts – stiffened tension panels, tension beams, and stiffened outer shell plates – are welded and prepared separately, then assembled into blocks before the main assembly of the entire tank structure takes place.

Insights & Innovations from the Future of Energy Containment

Discover how our containment solutions are enabling progress across maritime, energy, and industrial sectors. From fuel transitions to carbon capture, our stories explore the real-world challenges, technologies, and breakthroughs shaping a low-carbon future.

Meet our team

The management team of Lattice International AS consists of individuals with broad international experience and world-class expertise, committed to deliver cutting edge solutions for the global energy- and transportation industry.

Jon E. Bergan

CCO

Jon E. Bergan

CCO

Jørgen F. Agerup

COO

Jørgen F. Agerup

COO

Paal Braathen

CEO

Paal Braathen

CEO

Frequently Asked Questions

Need more details? Reach out to our team for tailored information.

Our patented LPV technology enables safer, more efficient, and scalable storage for LNG, hydrogen, ammonia, CO₂, and any other liquefied gas, reducing costs and supporting global decarbonization goals.

LATTICE serves a range of industries focused on energy transition and emissions reduction. This includes maritime shipping, energy infrastructure, carbon capture and storage (CCUS), industrial decarbonization, and green mobility. Our containment solutions are designed to adapt across sectors where storing or transporting liquefied or compressed gases is critical.

The LATTICE Pressure Vessel (LPV) is a prismatic, high-pressure containment system, unlike traditional cylindrical tanks. Its shape allows it to maximize space efficiency and fit into challenging layouts — such as ship hulls, terminals, or compact industrial sites. LPVs also reduce system complexity by requiring fewer tanks to store the same volume of gas, leading to simplified integration, lower cost, and better performance.

Yes. LPV technology is designed for versatile deployment across both onshore and offshore environments. From floating LNG units and CO₂ injection vessels to onshore terminals and manufacturing facilities, LPVs provide scalable and certifiable storage performance in high-pressure, low-temperature conditions — regardless of location.

LPVs enable the safe and efficient storage of low-carbon and zero-emission fuels like hydrogen, ammonia, and liquefied CO₂. They are also used in onboard carbon capture systems, allowing vessels and industrial sites to reduce emissions without waiting for new infrastructure. By lowering the cost and increasing the feasibility of clean energy storage, LPV technology helps accelerate the transition to net-zero operations.