Accelerating the Maritime Industry Efficiently Towards Net Zero

Maximize vessel performance and profitability while reducing emissions — with compact, high-performance fuel and cargo containment systems tailored to your fleet. LATTICE’s LPV technology helps you unlock space, value, and future readiness in every voyage.

More Cargo. More Fuel. Same Hull.

Unlock hidden capacity and revenue by optimizing how space is used onboard.

Ready for the Fuels of Tomorrow.

From LNG to NH₃ and LH₂ — our LPV tanks support your transition to net zero, step by step.

Verifiably Impactful Results.

Real-world case studies show significant gains in fuel efficiency and cargo volume.

Proven Safety & Compliance.

Technology approved by ASME, US Coast Guard, and major Classification Societies.

LPV Fuel Solution

Every cubic meter on board matters — especially when it comes to fuel storage. Our LPV (Lattice Pressure Vessel) fuel tanks are designed to fit seamlessly within your ship’s hull, unlocking space you didn’t know you had. The result? Longer range, more payload capacity, and greater operational flexibility.

Whether you’re powering with LNG, ammonia (NH₃), hydrogen (LH₂), or using a dual-fuel strategy, our LPVs are engineered to match your vessel’s specific layout, energy demand, and environmental targets — without compromising commercial performance.

- Fully integrated into the ship’s structure

- Custom-fitted for maximum space utilization

- Compatible with current and next-gen fuels

- Designed for IMO compliance and net-zero readiness

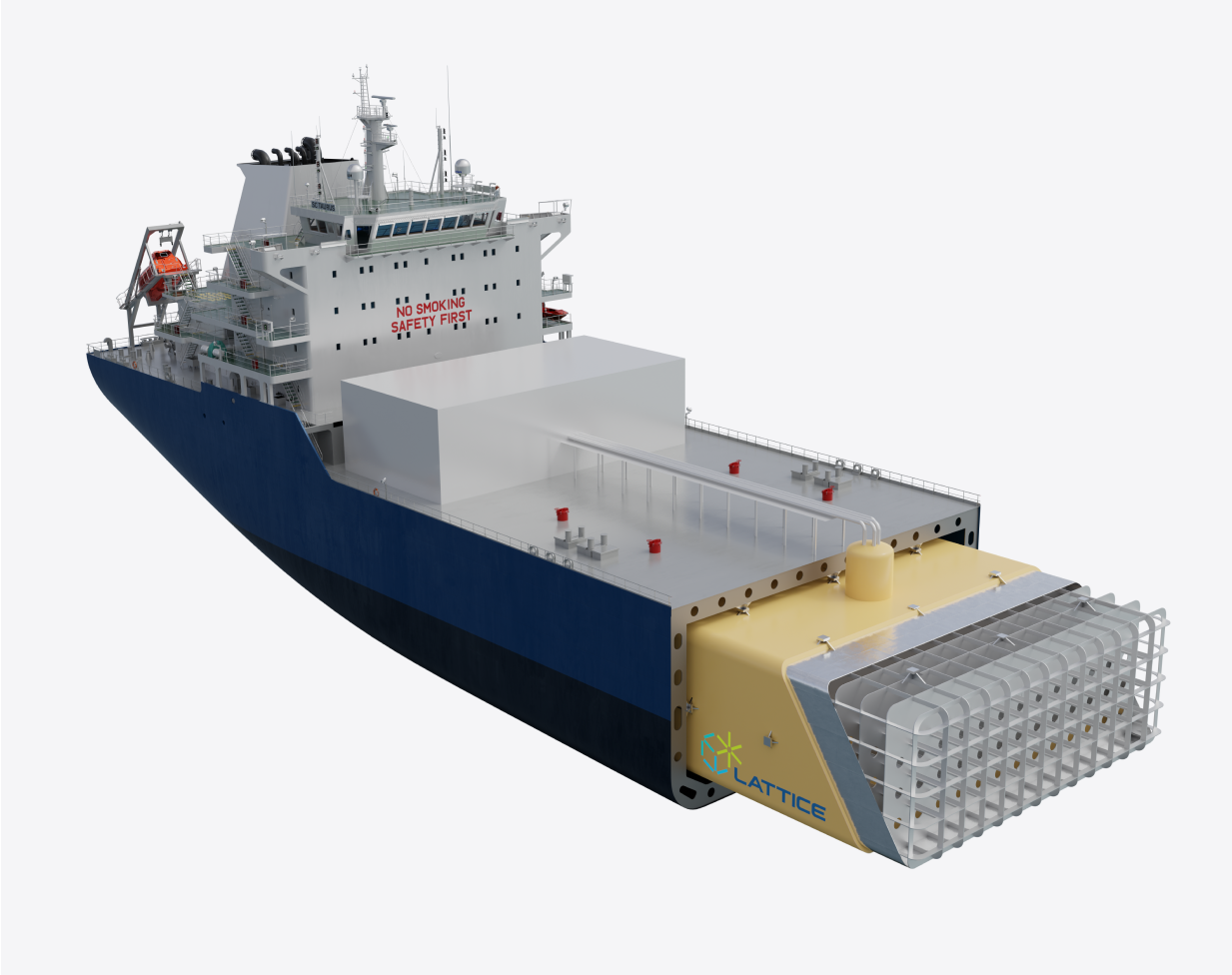

LPV Cargo Solution

When transporting liquefied gases, traditional tank designs often waste space and increase system complexity. LPV cargo tanks change that.

Thanks to their pressure-resistant design and custom-fit form factor, LPVs can store larger volumes with fewer tanks — reducing the need for multiple connections, valves, and structural reinforcements. That means simpler engineering, faster integration, and lower overall cost.

- Scalable capacity for LCO₂, LH₂, LNG, and other energy commodities

- Fewer tanks required to meet bulk volume needs

- Flexible shapes fit into otherwise unused spaces

- Reduced weight and equipment footprint

Insights & Innovations from the Front Lines of Maritime Efficiency

Frequently Asked Questions About LPV Maritime Containment Solutions

Each LPV system is custom-engineered to fit your ship’s layout, fuel strategy, and performance needs. From shape and size to pressure rating and insulation type, we tailor every detail to ensure optimal results — with design support from concept to integration.

By fitting seamlessly into available onboard spaces, LPVs maximize storage without sacrificing cargo capacity. Fewer tanks are needed, simplifying onboard systems and reducing operational complexity — which translates into lower costs, longer range, and higher earning potential per voyage.

Absolutely. LPVs are ideal for cryogenic and compressed energy cargo, including liquefied CO₂ (LCO₂), LNG bunkering, and hydrogen carriers. Their pressure tolerance and modular scalability allow them to replace multiple traditional tanks — enabling simpler engineering and higher payload capacity.

Yes. LPV systems are certified and approved by ASME, US Coast Guard, and all major Classification Societies. You can trust our technology to meet the highest international standards for safety, reliability, and environmental compliance.

LPVs cater to a wide range of vessel types, including:

- Container vessels

- Car carriers

- Cruise ships & ROPAX

- Offshore support vessels (OSVs)

- LNG bunkering vessels /small-scale carriers

- LCO₂ and LH₂ carriers

If your ship needs to store fuel or energy cargo compactly and safely, LPVs are a smart investment.

Each LPV system is custom-engineered to fit your ship’s layout, fuel strategy, and performance needs. From shape and size to pressure rating and insulation type, we tailor every detail to ensure optimal results — with design support from concept to integration.

Yes. LPV technology is fully compatible with LNG, NH₃ (ammonia), LH₂ (liquid hydrogen), and dual-fuel systems. Each tank is tailored to the physical and regulatory requirements of the fuel in use — ensuring safe operation today and flexibility for future fuel transitions.