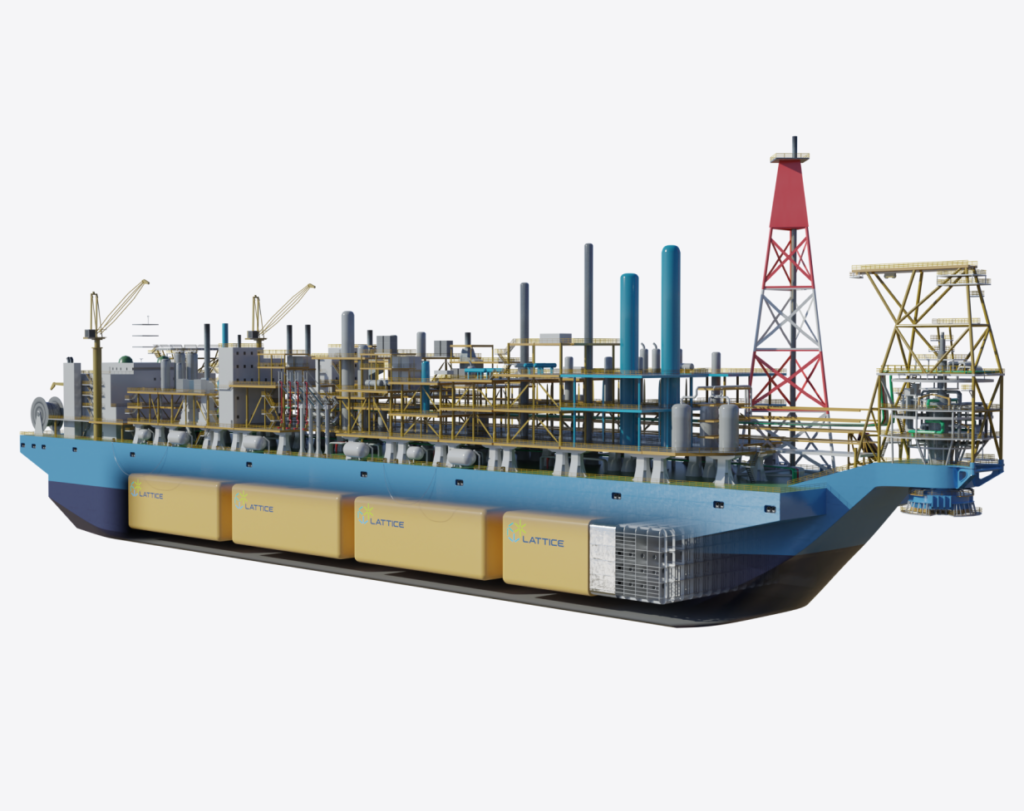

Floating Storage Units are no longer limited to offshore oil and natural gas operations. As global energy systems shift toward decarbonization, FSUs are emerging as critical infrastructure for storing liquefied carbon dioxide and ammonia. These gases are key to carbon capture and storage as well as clean fuel logistics.

Whether permanently moored offshore or positioned alongside a jetty, FSUs must balance process complexity with structural efficiency. The ability to store large volumes of liquefied gases while maintaining a compact hull is now essential to lowering project costs and enabling faster deployment.

Why FSUs Demand Smarter Storage Solutions

Traditional FSUs equipped with cylindrical or bilobe tanks face several challenges. Their shape does not align with the optimal geometry of compact floating assets. This leads to inefficient use of space, higher steel weight, and increased operating costs.

Floating units also face tough marine environments, making hull size, stability, and structural simplicity important design drivers. Compact and efficient FSUs can lower not only fabrication costs but also the footprint of mooring systems, jetties, and associated infrastructure.

As the demand for LCO₂ and liquefied ammonia increases, FSUs must become smarter, more flexible, and capable of operating across a wide range of pressure and temperature conditions. LPV tank technology offers a direct path to meeting these needs.

How LPV Storage Tanks Optimize FSU Design and Performance

LPV, or Lattice Pressure Vessel, storage tanks are designed to fit the asset—not the other way around. Their prismatic and modular nature allows designers to maximize every cubic meter inside the hull. LPV tanks can handle pressures exceeding 30 barg and temperatures from minus 253 to plus 45 degrees Celsius, covering a wide spectrum of liquefied gas types.

Because LPV tanks can be custom shaped, fewer tanks are needed. This reduces complexity, equipment count, and overall system weight. It also means FSUs can be built smaller, with better balance and less environmental impact, while maintaining or increasing total storage capacity.

Volume Utilization That Translates to Financial Advantage

LPV tanks make it possible to reach superior volume utilization compared to traditional cylindrical options. This allows asset owners to either reduce the size of the FSU or increase its capacity without expanding the hull.

In both retrofit and newbuild projects, this translates directly into capital expenditure savings, lower steel and material use, reduced energy consumption during operations, and overall better economic returns. It also opens up the possibility of using existing vessel designs as cost effective FSUs with upgraded containment capabilities.

Scalability and Flexibility Across Gas Types

One of the standout benefits of LPV technology is its scalability. Whether storing ten thousand cubic meters or one hundred thousand, LPV tank configurations can be scaled accordingly without changing the tank concept. Fewer tanks mean fewer connections, less instrumentation, and lower maintenance costs.

This makes LPV tanks especially attractive for future floating applications where adaptability and modularity are vital. Whether the project is focused on LCO₂ injection, ammonia bunkering, or long term gas storage, LPV technology can be configured to support the pressure and temperature profile required.

A Platform for Long Term, Low Emission Infrastructure

As the world accelerates investment in carbon capture and alternative fuels, floating storage platforms will play a central role in enabling infrastructure where land based storage is not feasible or cost effective. LPV storage tanks provide the technical foundation needed to build these platforms efficiently and at scale.

By enabling smaller, smarter, and more adaptable FSUs, LPV technology becomes a critical tool in lowering the cost per cubic meter of stored gas and in accelerating the rollout of climate focused energy logistics.

Conclusion: LPV Storage Tanks Make FSUs Future Ready

Floating Storage Units are essential to the future of decarbonized fuel and carbon logistics. LPV storage tanks transform the FSU from a conventional marine asset into a streamlined, high performance storage platform.

They deliver space efficiency, structural flexibility, and operational reliability while reducing both capital and operating costs. Whether used for liquefied carbon dioxide or ammonia, LPV tanks make FSUs more cost efficient, scalable, and aligned with the future needs of clean energy value chains.