Offshore support vessels (OSVs) and passenger/RO‑PAX vessels face a common challenge: limited available real‑estate for fuel tanks, cargo or passengers. These vessels must balance fuel storage for range, safety and operational flexibility against preserving deck space for high‑value payloads, passengers or equipment. When switching to low‑carbon fuels like LNG, ammonia or hydrogen, which often have lower energy density, storage volumes increase and spatial efficiency becomes critical. The introduction of LPV (Lattice Pressure Vessel) fuel tank solutions offers a way to address these constraints by optimizing tank geometry and reclaiming valuable space.

OSVs: Doubling Range Without Sacrificing Payload

For OSVs operating offshore in support of oil, gas or wind‑farm installations, every square metre counts. Fuel storage must not impede cargo holds, equipment decks or deployment spaces. By applying a tank concept that uses a lattice structure and box‑shaped volume instead of a conventional cylindrical vessel, it becomes possible to nearly double fuel volume in the same tank hold footprint. This means longer range, fewer port calls and less downtime while maintaining payload capacity and deck functionality.

Case Study: +100 % Fuel Volume, +US 720 000 Revenue per Year

In a project for a PSV (platform supply vessel) the operator replaced conventional cylindrical dual‑purpose fuel tanks with optimized LPV tanks. Within the same tank hold space the total fuel volume almost doubled. The increased range reduced required port calls from 24 to 12 per year. With an average day rate of USD 20,000 and 3 days per port call (1 day sailing to shore, 1 day in port, 1 day sailing offshore), this translated into roughly USD 720,000 additional annual revenue. Over a typical 20‑year vessel lifetime the uplift was calculated at approximately USD 14,400,000.

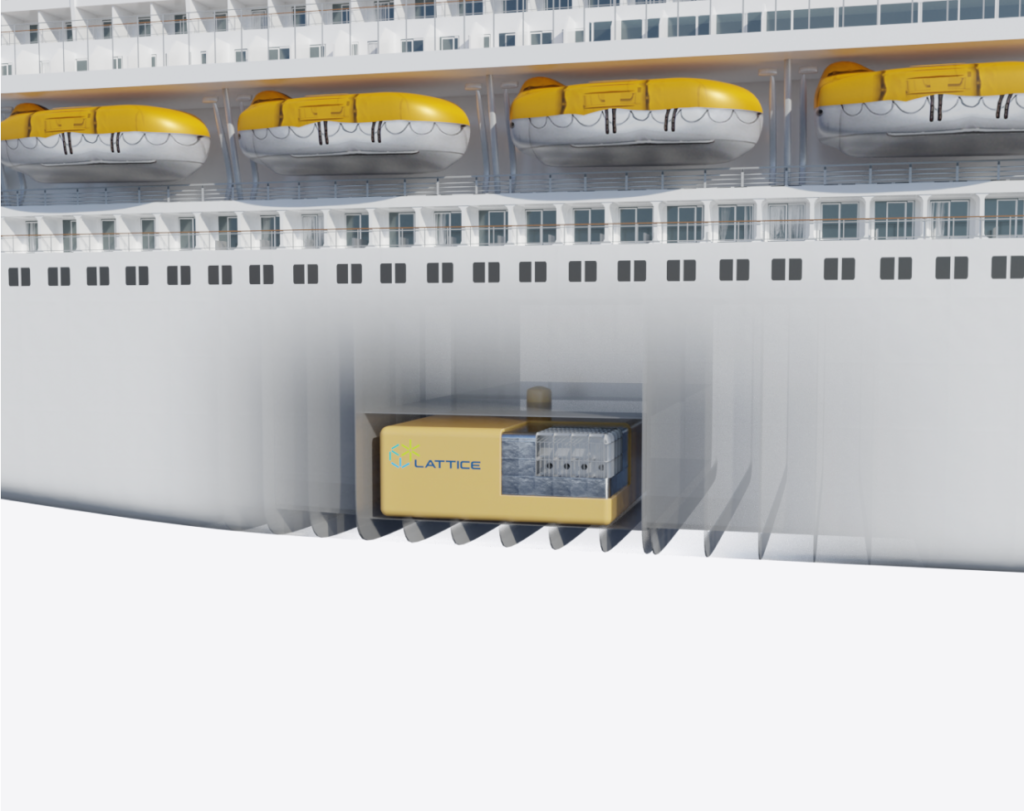

Cruise & ROPAX: Lower Emission Fuels = Bigger Tanks

Cruise ships and RO‑PAX (roll‑on/roll‑off passenger) vessels are under increasing pressure to adopt greener fuels. Many are now running on LNG, or preparing for ammonia or hydrogen. These fuels require greater volumetric capacity to match the sailing range of traditional fuels due to their lower energy densities. Large cruise and RO‑PAX vessels often have LNG fuel tanks in the 500–3,000 m³ range, which can significantly affect deck space and vessel architecture. By integrating an LPV design, operators can minimise the space impact of fuel storage, preserve passenger or cargo decks and maintain operational economics.

LPV Solutions for LNG, Ammonia, Hydrogen

LPV fuel tanks are inherently future‑ready. Because the structure is modular, box‑shaped and built to adapt to the available hull space, it allows for:

- LNG fuel storage today with conversion readiness for ammonia or hydrogen tomorrow.

- Accommodation of lower energy‑density fuels without sacrificing space or payload.

- Integration in new‑build or retrofit projects across vessel types.

In effect, LPV becomes a bridge technology that supports decarbonisation without penalising vessel performance or capacity.

Retrofitting & Newbuilds: Flexibility in Design

Whether you are planning a new vessel or considering a retrofit of an existing one, LPV fuel tanks provide architectural flexibility. In new‑builds the hull can be designed around the tank layout rather than shoehorning a cylindrical tank into the ship. In retrofit scenarios the tank shape can be tailored to existing hull spaces, putting fuel in lower‑value compartments and freeing up prime decks. This flexibility enhances lifecycle value and allows operators to optimise both cost and space.

Compliance, Classification & ASME Approval

Fuel tanks for marine vessels must satisfy rigorous standards for safety, strength, pressure containment, insulation and classification society approval. LPV tanks have been developed to meet these requirements, are compatible with major classification societies and comply with ASME standards. This ensures that vessel owners and operators can deploy LPV technology with confidence and stay ahead of regulatory demands around zero‑emission fuels.

Conclusion: Space‑First Design = Profitable, Future‑Proof Vessels

Fuel storage design should not be an afterthought—it must be central to vessel architecture and commercial strategy. For OSVs and passenger/RO‑PAX vessels, spatial efficiency directly influences the bottom line. LPV fuel tanks offer a practical way to double fuel volume, preserve or increase payload capacity, and position vessels for the future of marine fuels. By adopting a space‑first mindset, operators unlock greater profitability, higher operational flexibility and a clear path toward decarbonisation.

Optional FAQs

Q: Can LPV tanks truly double fuel volume in the same footprint?

A: Yes. According to case studies, LPV technology has achieved nearly 100 % increase in fuel volume within the same tank hold space for certain vessel types.

Q: Are LPV tanks suitable for retrofit applications?

A: Absolutely. LPV tanks are designed to fit the available hull space and can be integrated into existing vessels for improved space utilisation and performance.

Q: How does LPV support future fuels like ammonia or hydrogen?

A: LPV tanks are engineered with flexibility in mind. Their modular structure and tailored shape allow conversion or adaptation for low‑ or zero‑carbon fuels without major redesign.

Q: Will using LPV tanks impact vessel safety or certification?

A: No. LPV tanks are designed to meet ASME standards and major classification society requirements for marine fuel storage.

Q: How should vessel operators evaluate the benefit of LPV tanks?

A: Key criteria include: available hull or deck space, current fuel tank volume and requirements, cargo or passenger space value, potential port call reduction, fuel transition strategy and lifecycle revenue uplift.