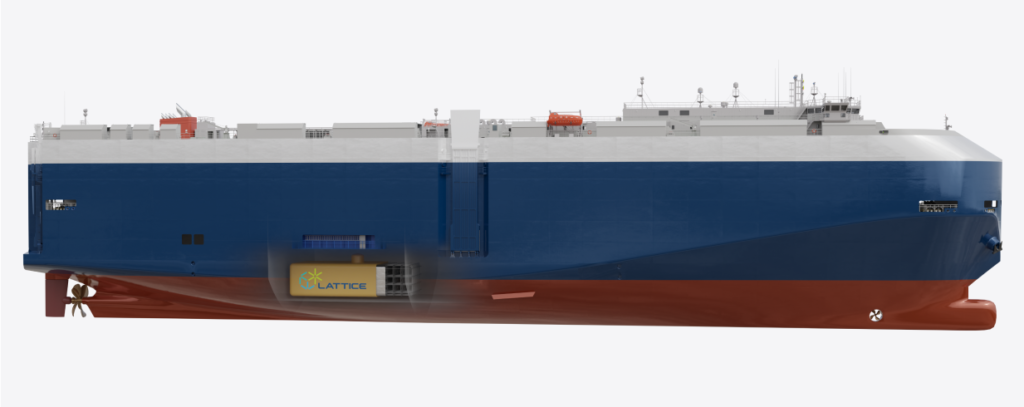

In the highly competitive world of container shipping, every square metre onboard counts. Whether you’re operating a feeder vessel or a mega‑size 10,000+ TEU ship, the primary goal remains the same: carry as many containers (and thus generate as much revenue) as possible from A to B. The challenge? Traditional cylindrical or bilobe fuel tanks still common in many LNG‑fuelled vessels—do not conform well to the box‑like, prismatic cargo holds of container ships. They leave unusable “odd” voids, reduce cargo capacity, and occupy space that could otherwise be revenue‑earning. Enter the next generation solution: the ℅ LATTICE International Lattice Pressure Vessel (LPV) fuel tank. By rethinking tank geometry, shipping operators can unlock real space, real containers and ultimately real profit.

The Space Problem with Conventional Tanks

Conventional LNG fuel tanks are typically cylindrical or bilobe in shape. While effective in pressure containment, they are spatially inefficient for container vessels.

- Cylindrical tanks leave awkward, unused corners when installed inside prismatic hulls.

- More space is required to store the same volume of fuel.

- The result is fewer containers carried and reduced profitability per voyage.

As the industry transitions to lower-emission fuels like LNG and ammonia — both with lower energy density than marine gas oil — the need for larger tanks grows. That means even more pressure on space.

LPV: A Smarter Alternative for LNG and Future Fuels

LPV tanks are engineered to match the natural geometry of the ship. Instead of adapting the ship around the tank, LPV adapts the tank to the ship.

Key benefits include:

- Prismatic design fits snugly within the ship’s hull.

- Internal lattice structure supports high pressure without requiring thicker walls.

- Up to 50 percent more efficient use of space compared to cylindrical tanks.

- Configurable for dual-fuel use or future fuel types like ammonia or hydrogen.

By optimizing how fuel is stored, LPV tanks help vessel owners maintain performance and compliance without compromising cargo capacity.

Real-World Results: 113 Extra TEUs on a 10,000 TEU Vessel

In one case study, a 10,000 TEU container vessel replaced a bilobe fuel tank with an LPV solution. The result was a gain of 113 additional TEU slots.

That’s 113 extra containers per voyage without changing fuel volume or range. It’s not just about space savings — it’s about unlocking capacity that directly boosts the bottom line.

Financial Impact: 4 Million USD in Additional Annual Revenue

Those 113 extra TEUs can lead to dramatic financial gains. For a vessel operating at consistent freight rates, the added capacity translates to approximately 4 million US dollars in extra revenue every year.

Over a vessel’s 20-year lifespan, that equals more than 100 million dollars in added earnings. This is a direct result of smarter fuel tank design.

Future-Proofing the Fleet: Ammonia and Dual-Fuel Ready Tanks

LPV fuel tanks are designed with flexibility in mind. As the shipping industry moves toward alternative fuels like ammonia and hydrogen, the need for adaptable storage solutions becomes critical.

LPV tanks can be:

- Installed as LNG tanks today and converted to ammonia in the future.

- Sized to handle lower energy density fuels without expanding footprint.

- Integrated seamlessly into both newbuilds and retrofits.

This future-ready design ensures vessel owners can transition fuels without costly redesigns or lost cargo space.

Why LPV Gives Container Operators a Competitive Edge

In a competitive global shipping market, every advantage matters. LPV tanks give operators a strategic edge by:

- Increasing container capacity without increasing vessel size.

- Boosting annual and lifetime revenue.

- Enhancing ship resale and charter value.

- Supporting sustainability goals and regulatory compliance.

- Offering a flexible design for future fuel transitions.

It’s a space-saving solution that translates into long-term profitability.

Conclusion: Unlock Your Vessel’s Full Potential

Fuel storage should no longer be treated as a fixed constraint. With LPV fuel tanks, operators can reimagine how space is used onboard. The result is increased cargo capacity, higher revenue, and a future-ready vessel.

Whether planning a newbuild or exploring retrofit options, LPV technology provides a smarter way to store fuel and unlock your ship’s true earning potential.

FAQs

Q: How much more space can LPV tanks provide compared to cylindrical ones?

A: LPV tanks can improve volume utilization by 20 to 50 percent, with many cases averaging around 30 percent gains.

Q: Are LPV tanks certified for marine use?

A: Yes, LPV designs have received approvals from major classification societies and meet international standards for LNG and future fuels.

Q: Can LPV tanks be retrofitted into existing vessels?

A: Absolutely. LPV tanks are designed for flexibility and can be adapted to fit available space in existing container ships.

Q: How does LPV support fuel transition strategies?

A: LPV tanks are dual-fuel capable and can be configured for LNG, ammonia, methanol, or hydrogen as needed, supporting long-term sustainability.

Q: Will an LPV tank impact vessel range or operational flexibility?

A: Not at all. In fact, better space utilization often means increased fuel capacity and range, with reduced need for port calls.